| Type: | JW-4010 | JW-5020 | |

| Detection window size | 400*150mm | 500*200mm | |

| Machine size | 1620*700*800mm | 1620*800*900mm |

Send E-mail

Send E-mail

Consult Now

Consult Now

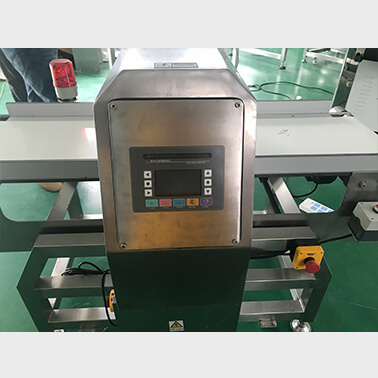

Brief Introduction:

Metal detector is specially used for the detection of iron, nonferrous metals and alloy impurities in food and medicine. To detect all kinds of metal fragments in chemical raw materials, rubber products and paper products.

Feature:

Adopting the balance principle more widely used in foreign metal detection equipment, it has more stability, reliability and better performance.

DSP and MCU are combined to sample and process the detected signal, which improves the detection effect.

A good man-machine dialogue interface.

Can detect iron, stainless steel, copper, aluminum and other non-ferrous metals and other materials; With self-learning function, the detection range of materials is expanded.

With memory function, it can store test parameters of 20 products.

It is convenient to adjust the sensitivity. The detection sensitivity can be reached as follows: stainless steel SUS reaches_1.5 mm, iron FE reaches_0.7 mm (500 MM 200 mm window)

Conform to the HACCP certification standard.

Working Principle:

Usually metal detector consists of metal detector and automatic rejection device, in which the detector is the core part. There are three groups of coils in the detector, namely the central transmitting coil and two reciprocal receiving coils. The high frequency variable magnetic field is produced by the oscillator connected by the middle emitting coil. Once the metal impurities enter the magnetic field area, the magnetic field is disturbed, the balance is broken, the two receiving coils of the inductive voltage can not be offset, the uncompensated inductive voltage is amplified by the control system, and an alarm signal (metal impurities detected) is generated. The system can use the alarm signal to drive the automatic removal device and so on, thus excluding metal impurities from the production line.

Technical Data:

|

Model |

JW-4010 |

JW-5020 |

|

Theory |

Balanced Coil |

|

|

Detection window size |

400*150mm |

500*200mm |

|

Alarm |

Buzzer & lamp |

|

|

Conveyor speed |

32m/min |

|

|

Power |

Appr. 200w |

|

|

Machine size |

1620*700*800mm |

1620*800*900mm |

|

Net weight /Gross weight |

160kg/260kg |

200kg/300kg |

|

Remarks |

Also can be customized as requested |

|

INQUIRYContact us now if you have any question about our company and products.

INQUIRYContact us now if you have any question about our company and products.