Biscuit Prodcution Line

Cookie Production Line

Potato Chips Production Line

Fried Peanut Production Line

Onion Roll Production Line

Fruit and Vegetbale Production L...

Juice Production Line

Pulp Production Line

Cookie Production Line

Brief Introduction

Brief Introduction

Cookie production line consists of mixing machine, cookie forming machine, baking oven, cooling belt, working table, packing machine. There are semi-automatic type and full-automatic type. Customers can choose according to their own needs. This line can be used for making Danisa cookies, whole-tray cakes, small cakes, puff etc.

Moulds:

.jpg)

.jpg)

.jpg)

.jpg)

Cookies green:

.jpg)

.jpg)

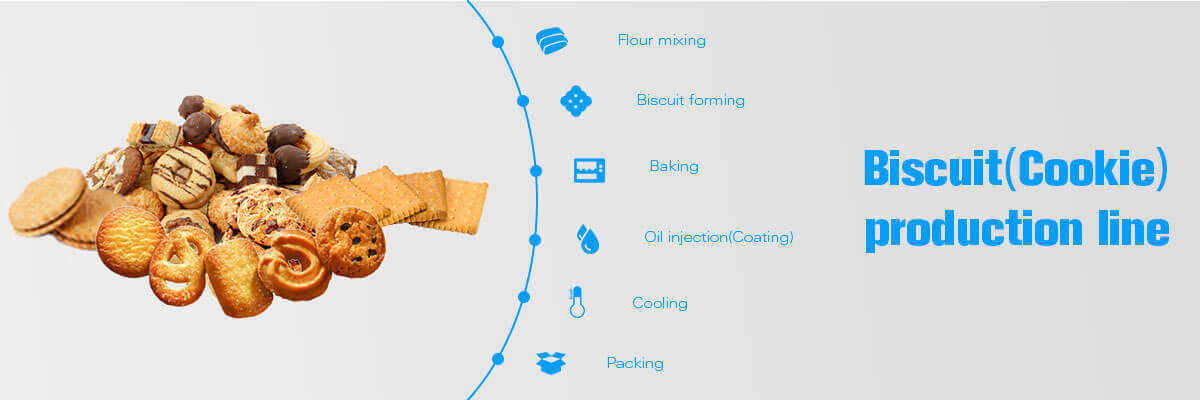

Working process

Working process

Semi-automatic production line:

Mixing machine -Cookie forming machine -Batch rotary baking oven -Working table -Packing machine

Full-automatic production line:

Dough mixer machine-Cookie forming machine (depositor, cutting, torsion, bracing)- Front drive -Tunnel baking oven- Back drive -Cooling belt- Working table-Packing machine

Equipment Characteristic

Equipment Characteristic

Cookie Production Line

Dough mixer:

It adopts the principle of planetary motion, the agitator for planetary motion in the barrel, so that the food thoroughly mixed.

Cookie forming machine:

This machine is kind of forming machine which can produce various kinds of snacks, cookies and biscuits. Put into well-mixed dough, by changing different depositor mold, cutting mold etc, to make cookies and biscuits of various shape. PLC control available.

Rotary oven:

It adopts hot air circulation system and rotary baking carts, so that all the materials heated evenly. Equipped with lighting system, we can clearly observe the baking process of food through the glass door. There are three heating ways available for chosen, electric, gas and diesel. It’s the best baking equipment of cookies, bread, cake, moon cake and other snacks.

Tunnel oven:

It is composed of an oven tunnel, mesh belt, chain, transmission system, chimney, electric heating pipe and a control box. This oven adopts infrared electric heating to make snacks evenly heated, Speed can be adjusted, precise control of oven temperature, the oven is generally divided into 4 meters as one part, and, divided into several different temperature zones of which, the temperature can be controlled separately.

Cooling device:

This cooling device is used to make sure the biscuits fully cooled before delivered to the packaging platform, which ensures the quality of the biscuit package and the extended shelf life.

Packing machine:

We can equip different packing machine to meet different packing requirement, packed in trays, independent bags, or boxes etc.

Production capacity

Production capacity

| Model |

Mold |

Voltage |

Power |

Capacity |

Tray Size |

Dimension |

|---|---|---|---|---|---|---|

| QQJ-400 |

7 |

220~380/50Hz |

0.75kw |

100~150kg/h |

400*600mm |

1400*900*1300mm |

| QQJ-600 |

10 |

220~380/50Hz |

1.5kw |

180~250kg/h |

600*400/ |

1400*1100*1400mm |

| QQJ-800 |

13 |

220~380/50Hz |

3kw |

280~350kg/h |

800*400/ |

1800*1300*1400mm |

| QQJ-1000 |

16 |

220~380/50Hz |

4.5kw |

350~450kg/h |

1000*400/ |

2000*1500*1500mm |

Delivery

Delivery

Kindly remind

Kindly remind

Only we know you well so we can serve you better.

Question:

Do you have any sample pictures(size) of the biscuits or cookies that you want to make, and please tell us the capacity you need.

Do you have any sample pictures(size) of the biscuits or cookies that you want to make, and please tell us the capacity you need.

Is this the first time to start biscuits(cookies) business ,or want to expend your current business.

Is this the first time to start biscuits(cookies) business ,or want to expend your current business.

Do you already have the factory(shop), or on planning, if yes, please tell us the workroom’s(shop’s) size.

Do you already have the factory(shop), or on planning, if yes, please tell us the workroom’s(shop’s) size.

Is there any budget about this business plan.

Is there any budget about this business plan.

Solution:

Depend on all your situation and requirements, our engineer with more than 20 years experience can offer you the best solution, save your time , save your money.

INQUIRYContact us now if you have any question about our company and products.

INQUIRYContact us now if you have any question about our company and products.