Biscuit Prodcution Line

Cookie Production Line

Potato Chips Production Line

Fried Peanut Production Line

Onion Roll Production Line

Fruit and Vegetbale Production L...

Juice Production Line

Pulp Production Line

Potato Chips Production Line

Brief Introduction

Brief Introduction

Small-scale semi-automatic chips production line:

The line only include 8 single machines such as potato washing peeling machine ,cutting machine, blanching machine , dewatering machine ,frying machine ,deoling machine , flavoring machine and vaccum packing machine . The line is of low investment, big and fast profit, easy operation and high quality if you want to produce frozen French fries. You can add a freezer and remove the flavoring machine.

Automatic chips production line :

The line is of high automation, large capacity, low energy consumption, small area occupation, easy operation, good quality and high profit. The line mainly include the process of potato washing peeling, cutting, washing, blanching, dewatering frying, deoiling, flavoring and packing. We will provide formula and technology guidance to make sure you can make high quality and delicious potato chips. With small changes, and add freezer to the line ,you can frozen French fries.

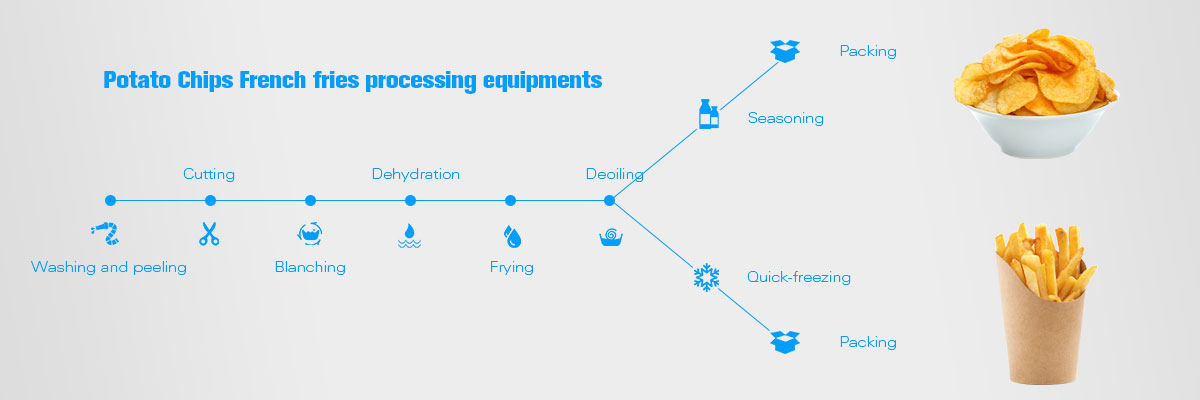

Working process:

Working process:

Washing and peeling-Cutting- Blanching- Dehydration- Frying- Deoiling- seasoning- Packing

Equipment characteristic

Equipment characteristic

Small-scale semi-automatic chips production line:

Potato washing and peeling machine:

can do the cleaning and peeling process at one time, has high efficient and low consumption.

Potato cutting machine:

can cut flake and filiform shape, and the size and the thickness can be adjusted.

Blanching machine:

For lifting and transportation of materials, artificial materials can easily fall into the hopper, continuous, uniform material will be elevated through the conveyor belt to the next step, 304 stainless steel mesh belt conveyor, hopper with a stone sink device, the material on sand soaked by precipitation and outfall discharge, easier to clean, peeled.

Small-scale semi-automatic chips production line:

do rinsing and color protection of the cut potato chips. ;

Frying machine:

has the exact temperature of the oil, can make the potato chips quality and taste.

De-oiling machine:

use the centrifugal, overcome the shortcoming of botheration.

Seasoning machine:

make the potato chips turning even, use the spray type to add the seasoning, not easy to break.

Nitrogen filled packing machine:

when packing, put into nitrogen, can avoid break of the potato chips. And it can aeration, package, and type the date at one time.

Automatic chips production line:

Elevator lifting machine :

For lifting and transportation of materials, artificial materials can easily fall into the hopper, continuous, uniform material will be elevated through the conveyor belt to the next step, 304 stainless steel mesh belt conveyor, hopper with a stone sink device, the material on sand soaked by precipitation and outfall discharge, easier to clean, peeled

Spiral cleaning peeling machine

is mainly composed of motor, gearbox, wool roller, using brush principle, widely used in cleaning and peeling round, oval fruits and vegetables. Using the propulsion of spiral vane, water operation,to achieve automatic continuous washing, can be used with production line.

Picking machine:

Using the mesh belt transmission to the next procedure at the same time picking a peel defect or incomplete material, picking, convenient, save time and effort and continuous operation. After picking the material by this device can continuously even promoted to cutting equipment, save a lot of labor, increase production.

Potato cutting machine:

It can cut the potato into slice and chips. The thickness of potato chips and potato slices is adjustable. Apply for potato, carrot,eggplant ,etc.

Rinsing machine:

Equipment has a bubble generator, the materials become rolling state, effectively remove material surface starch and impurities, debris from the overflow tank overflow, sediment from the discharge outlet, in order to achieve the purpose of cleaning. Clean thoroughly, energy saving, water saving, equipment is stable and reliable, etc.

Blanching machine:

Stainless steel wire mesh with automatic transmission, convenient operation, high efficiency. Heating parts, automatic temperature control, random setting, the heat source can use gas heating, electric heating, etc. Color can add food additives at the same time, to ensure that potato chips bright color, crispy, the body is stainless steel material, achieve the food sanitation standards.

Rinsing and cooling machine:

7.Crisps potato chips after blanching will have a certain quantity of heat, and there will be a touching together, using bubble up and down the rolling imitation hand rub repeatedly, can quickly put the crisps chips down surface temperature, prevent excessive material for blanching, and scatter material fully, is advantageous to the uniform level of the Fried, finally through the mesh belt conveyor into the next procedure to continue processing

Dehydration machine:

The potato chips are conveyed by the belt, the multi-faceted fan will blow potato chips uniformity. The food will be cooled by the high-pressure wind power of the fan, the surface water will be evaporated in a short time, effectively prevent the condition of oil jumping and shorten the frying time.

Frying machine:

Fried line machine for stainless steel manufacturing, sturdy, control temperature. By electric heating, coal heating, gas heating three ways, thermal efficiency is above 95%, save energy, equipped with automatic filter oil machine slag, no carbon in the oil, oil will not turn black, use cycle is long, Fried potato chips of bright color and good taste, improve the grade of products.

Deoiling machine:

Fried potato chips after approved by the mesh belt conveyor and the high pressure fan wind cooling the surface oil and driven away quickly, the wind the wind blade shape, effectively increase the air pressure, make the material chips the oil content of blowing off in a short time, equipment is equipped with oil pan, disallowed oil can be collected through oil pans and use again, save the oil at the same time can make chips not greasy taste better, convenient to store.

Flavor mixing machine:

Roller is equipped with a hopper above and seasoning evenly continuous on the drum, through the roller rotation seasoning mix material on potato chips and discharging mouth has the hook, can sieve out the remaining seasoning and collect the reuse, not only uniform mixing materials and guarantee the integrity of potato chips, convenient and practical.

Packaging machine:

This vertical packing machine is suitable to use in packing the high accuracy and easy fragile material , such as : puffy food , crispy rice , Potato Chips , Snacks , candy , pistachio , sugar , apple slices , dumpling , chocolate , pet food , small wares etc.

Production capacity

Production capacity

| Small scale | Capacity | Power | Weight |

| MKS50 | 50kg/h | 40.75kw/380v | 1260kg |

| MKS100 | 100kg/h | 74.8kw/380v | 1550kg |

| MKS150 | 200kg/h | 114.2kw/380v | 2760kg |

| Automatic line | Capacity | Power | Weight |

| MKA100 | 100kg/h | 181.84kw | 40000kg |

| MKA150 | 150kg/h | 242kw | 40000kg |

| MKA260 | 260kg/h | 259.2kw | 57000kg |

| MKA400 | 400kg/h | 326.98kw | 60000kg |

INQUIRYContact us now if you have any question about our company and products.

INQUIRYContact us now if you have any question about our company and products.